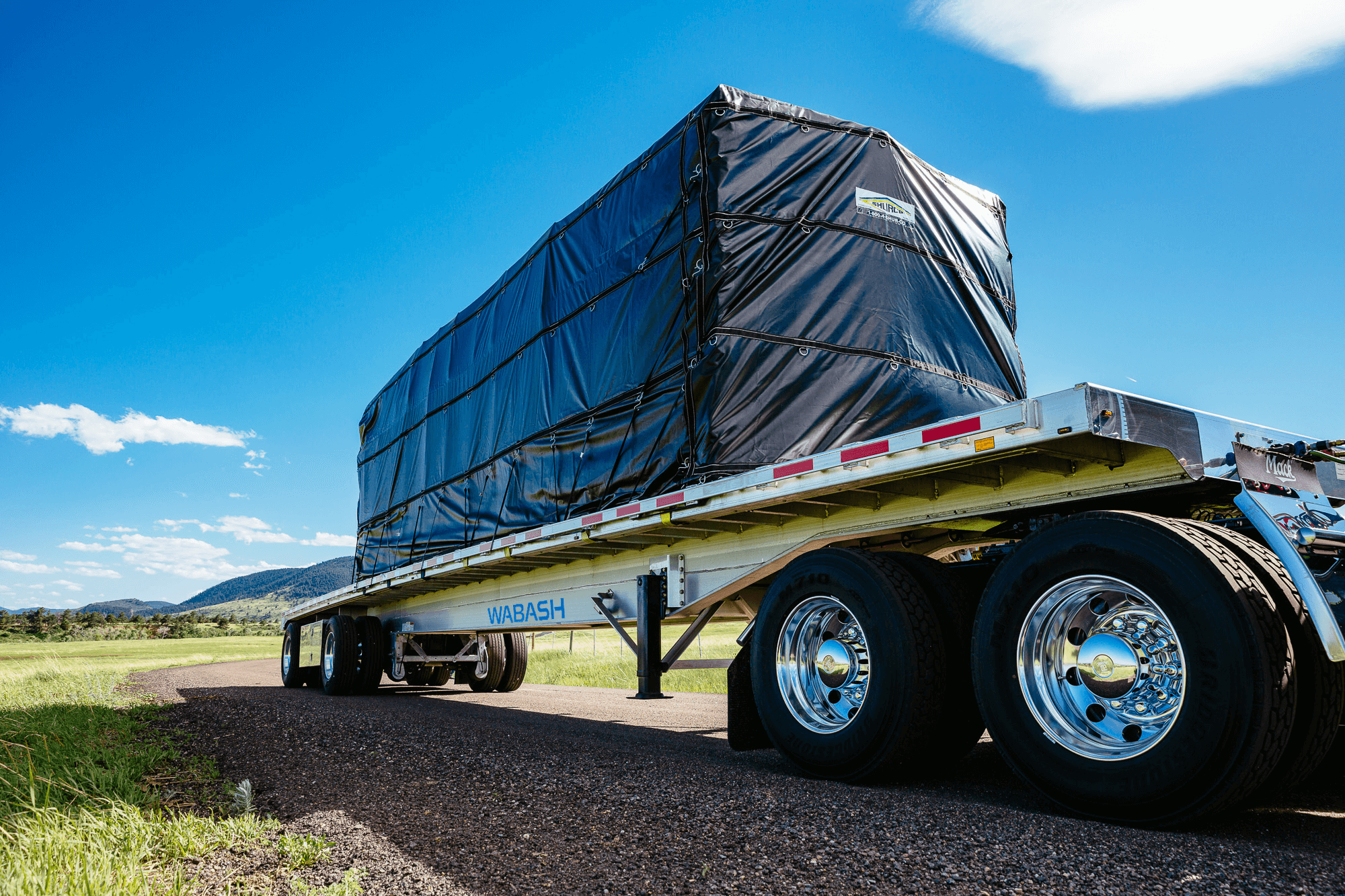

Trusted for Generations. Built for You.

Wabash Aluminum Flatbeds

Superior Main Beam. Lower Maintenance.

The two-piece, welded main beam design eliminates the need for mechanical fasteners by welding on the neutral axis—where bending stress is minimal. Unlike bolted designs, this beam has no fasteners that loosen over time, reducing maintenance needs and improving long-term reliability.

Less Weight. More Freight.

Floor crossmembers weld to the main beam, side rail, and floor to create a super-stiff structure. This eliminates the need for knee braces, resulting in a lighter trailer that delivers greater payload capacity and less ongoing maintenance.

Greater Flexibility. More Loaded Miles.

The Lock-Rite® multi-position tie-down system provides flexibility to secure loads either at the center or along the outer siderails using straps or chains. This flatbed also includes five additional stub crossmembers for steel coil support, with an optional full-length coil package available.

Better Highway Visibility.

The enhanced visibility lighting system features three stop/tail/turn lights and five dual-function side markers that also serve as turn signals. The one-piece tubular bumper includes an extruded grip surface, enhancing safety, visibility, and traction during operation.

Aluminum Flatbed Specifications

| Category | Details |

|---|---|

| General | Length: 28′–53′ Width: 96″ and 102″ |

| Beam Ratings |

524: 52,000 lb in 4′ / 57,000 lb in 10′ / 110,000 lb evenly distributed 624: 62,000 lb in 4′ / 68,000 lb in 10′ / 125,000 lb evenly distributed 724: 72,000 lb in 4′ / 78,000 lb in 10′ / 140,000 lb evenly distributed |

| 48′ Base Weights |

524: 8,712 lb / 3,952 kg 624: 8,842 lb / 4,011 kg 724: 8,952 lb / 4,061 kg |

| Main Beam Design |

• Welded, 2-piece, 6061 T6 extruded aluminum “T” cross sections • Beams welded along neutral axis • Floor sections welded to top flange • Top tee extrusion with Lock-Rite groove • Camber cut in lower “T” section |

| Front End Design |

• Bright aluminum front crossmember • Center mount glad hands and 7-way access panel • 5/16″ steel coupler plate bolted to beams/frame • Heavy-duty cross and aft bracing |

| Rear End Design |

• Closed section extruded rear light box • Three rear stake pockets with protector • Tubular bumper uprights with flange mounts • Grip surface on bumper • Rubber dock bumpers (3-bolt) • DOT and Transport Canada compliant |

| Siderail Design |

• Box section rail with Lock-Rite groove • Radius edges • Bolt-on “LL” winch track roadside • Stake pockets on 24″ centers • Double pipe spools • Rub rail with recessed groove |

| Crossmember & Floor System |

• 4-7/8″ aluminum C-channel on 16″ centers • Hollow core extruded aluminum floor boards • 4 apitong nailers (2 outer, double center) • Welded vertically and horizontally • Includes 5 extra stub crossmembers on 8″ centers |

| Undercarriage |

• Formed suspension crossmembers • Bolt-on lower steel C-channel & strut bracing • Air suspension with 5-year warranty • 121″ tandem widespread axle • “P” spindle wheel ends, alignment |

| Electrical / Lights |

• Air/electric via removable front plate • Below deck routing • Enhanced visibility lights, oval recess • LED lights, 5 per side • Flashing dual-function side marker lights • ABS braking system |

| Popular Options |

• Additional air/electric options • Aluminum components • Custom crossmember spacing • Corrosion prevention packages • Bumper filler plates • Disc brakes • Bulkheads, floor options • Storage, freight securement • Sliding/lift axles • Premium rear features |